Solved GATE Questions on Forming Process

Question 1. Match the following

| Product | Process |

| P.Molded luggage | 1. Injection molding |

| Q. Packaging containers for liquid | 2. Hot rolling |

| R. Long structural shapes | 3. Impact extrusion |

| S. Collapsible tubes | 4. Transfer molding |

| 5. Blow molding | |

| 6. Coining |

(A) P—1 Q—4 R—6 S—3

(B) P—4 Q—5 R—2 S—3

(C) P—1 Q—5 R—3 S—2

(D) P—5 Q—1 R—2 S—2

GATE-ME-2004

Hint 1. (Ans B)

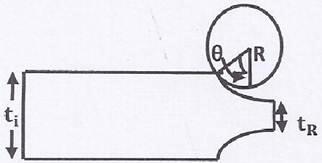

Question 2. In a rolling process, sheet of 25 mm thickness is rolled to 20 mm thickness. Roll is of diameter 600 mm and it rotates at 100 rpm. The roll strip contact length will be

(A) 5 mm

(B) 39 mm

(C) 78 mm

(D) 120 mm

GATE-ME-2004

Hint 2. (Ans B)

Given :

R = 300 mm, N = 100 r.p.m

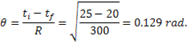

Angle subtended by the deformed at the roll center,

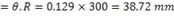

Roll strip contact length

Roll strip contact length

Question 3. Ten millimeter holes are to be punched in a steel sheet of 3mm thickness. Shear strength of the material is 400  and penetration is 40%. Shear provided on the punch is 2mm. The blanking force during the operation will be

and penetration is 40%. Shear provided on the punch is 2mm. The blanking force during the operation will be

(A) 22.6 kN

(B) 37.7 kN

(C) 61.6 kN

(D) 94.3 Kn

GATE-ME-2004

Hint 3. (Ans A)

Given shear strength

Sheet thickness t=3 mm

Diameter of hole,

D=10 mm,

Shear of punch,

Penetration of punch on fraction,

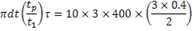

Blanking force when shear is applied on the punch

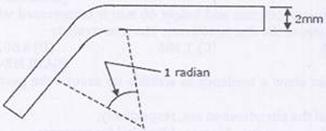

Question 4. A 2 mm thick metal sheet is to be bent at an angle of one radian with a bend of 100 mm. If the stretch factor is 0.5, the bend allowance is

(A) 99 mm

(B) 100 mm

(C) 101 mm

(D) 102 mm

GATE-ME-2005

Hint 4. (Ans C)

Question 5. Match the items in columns I and II.

| Column I | Column II |

| (P) Wrinkling | (1) Yield point elongation |

| (Q) Orange peel | (2) Anisotropy |

| (R) Stretcher strains | (3) Large grain size |

| (S) Earing | (4) Insufficient blank holding force |

| (5) Fine grain size | |

| (6) Excessive blank holding force |

(A) P-6 Q-3 R-1 S-2

(B) P-4 Q-5 R-6 S-1

(C) P-2 Q-5 R-3 S-4

(D) P-4 Q-3 R-1 S-2

GATE-ME-2006

Hint 5. (Ans D)

Wrinkling—Insufficient blank holding force

Orange peel—large grain

Stretcher strains—yield point elongation

Earing—Anisotropy

Question 6. In a wire drawing operation, diameter of a steel wire is reduced from 10 mm to 8 mm. The mean flow stress of the material is 400 MPa. The ideal force required for drawing (ignoring friction and redundant work) is :

(A) 4.48 kN

(B) 8.97 kN

(C) 20.11 kN

(D) 31.41 kN

GATE-ME-2006

Hint 6. (Ans B)

Question 7. A 4 mm thick sheet is rolled with 300 mm diameter rolls to reduce thickness without ant change in its width. The friction coefficient at the work-roll interface is 0.1. The minimum possible thickness of the sheet that can be produced that can be produced in a single pass is :

(A) 1.0 mm

(B) 1.5 mm

(C) 2.5 mm

(D) 3.7 mm

GATE-ME-2006

Hint 7. (Ans C)

Answer keys

1. (B), 2. (B), 3. (A), 4. (C), 5. (D), 6. (B), 7. (C),

2 Responses to “Previous Years GATE Questions on Forming Process 2004-2006”

amruta

goood

VIJJU

very good

VERY HELPFULL

BEST MATERIAL