To determine the COP and Tonnage capacity of the chilling plant.

Apparatus: – Compressor, Condenser, Evaporator, Capillary Tube, Ammeter, Voltmeter.

Theory: –

The apparatus consist of a hermitically sealed compressor which is fitted on the base of a M.S stand on a wooden stand. The compressed refrigerant from the compressor flows towards the air cooled finned condenser. After the condenser condensed refrigerant is collected in the receiver tank and from receive it passing through a filter drier and capillary tube and enter into evaporator (cooling coil) unit. Evaporator unit is a shell and tube type heat exchanger, which consist of stainless steel vassal and evaporator coil is wounded in this vassal (tank) an arrangement is provided to flow water to be chilled in this tank.

Flow rate of the chilled water is measured by using a Rota meter. Refrigerant after the evaporator unit is sucked back in compressor. Power input to the compressor is measured by using the energy meter which giving power consumed by compressor directly. A pressure and vacuum range is fitted on the control panel to measure pressure at the discharge and suction respectively. Digital temperature indicator is also fitted on control panel to measure temperature at different positions. A selector switch is provided over these by turning its position respective temperature may be noted.

Coefficient of Performance

The Co-efficient of performance of a chilling plant is given by the ratio of heat absorb to the work input.

COP = Heat removed by refrigerant / Power input

= m x Cp∆T / K.Wh

Where,

m = mass of water kept in the evaporator unit / mass flow rate of the water.

Cp = specific heat of water = 4.18 Kj /Kg K

∆T = temperature difference of chilling water

Kwh = power consumed by the compressor in unit time. Tonnage capacity:-

The capacity of a refrigeration machine is the refrigeration effect in a given time from a body. This capacity of machine is given by standard commercial tone of refrigeration. This is called as refrigerating effect i.e. melting of 1 ton of ice at 0° C in 24 hours.

TR = 336 x 1000 / 24 x 60 x 60 = 3.88 KJ / sec.

Tonnage capacity of the machine

= Net refrigerating effect of machine / 3.88

= m x CpΔT / 3.88

Temperature sensor details: –

1. T1 = Temperature Sensor : Fixed at Compressor Discharge Line

2. T2 = Temperature Sensor : Fixed after Condenser

3. T3 = Temperature Sensor : Fixed after Capillary Tube

4. T4 = Temperature Sensor : Inside Water Cooling Tank

5. T5 = Temperature Sensor : Fixed at Compressor Suction Line.

Procedure:

Switch on the compressor and let it to run for considerable time, until thermostatic switch starts functioning. Now fill the measured quantity of the water in evaporator or allow water to flow through the tank. Note down the reading of energy meter and initial temperature of chilling water and start stop watch and take the readings required for calculations in the table for certain interval.

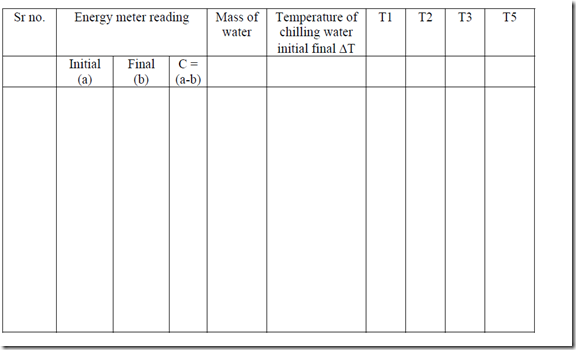

Observation Table

Sample Calculation

COP = m. CpΔT / KWh = 20 x 4.187 x (12) / 245 x 3.9

Tonnage capacity = COP / 3.88 TR

Precautions: –

1. Keep all the hand shut off valves tight closed until not required.

2. Keep small flow rate of the chilling water.

3. Compressor should not continuously for long time that should be hermetically cut down by the by the thermostat switch.

4. Do not disturb the copper piping, because it may cause leakage of the refrigerant from the system.

Result: –

Viva Questions: –

- · What is the purpose of chilling plant?

- · What is the use of thermostat control in ice plant?

- · What are the applications of ice plant?

- · What is freezing Drying?

- What is defrosting?