Solved Gate Questions on Casting

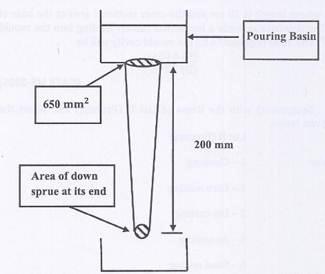

Question 1. A 200 mm long down sprue has an area of cross—section of 650  where the pouring basin meets the down sprue (i.e. at the beginning of the down sprue). A constant head of molten metal is maintained by the pouring basin. The molten metal flow rate is 6.5

where the pouring basin meets the down sprue (i.e. at the beginning of the down sprue). A constant head of molten metal is maintained by the pouring basin. The molten metal flow rate is 6.5  . Considering the end of the down sprue to be open to atmosphere and an acceleration due to gravity of

. Considering the end of the down sprue to be open to atmosphere and an acceleration due to gravity of  , the area of the down sprue in

, the area of the down sprue in  at its end (avoiding aspiration effect) should be

at its end (avoiding aspiration effect) should be

(A) 650.0

(B) 350.0

(C) 290.7

(D) 190.0

GATE-ME-2007

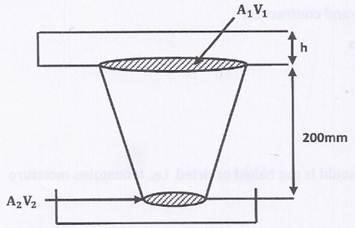

Hint 1. (Ans C)

Here, flow rate

At down,

Question 2. Volume of a cube of side ‘l’ and volume of a sphere of radius ‘r’ are equal. Both the cube and the sphere are solid and of same material. They are big cast. The ratio of the solidification time of the cube to the same of the sphere is

(A)

(B)

(C)

(D)

GATE-ME-2007

Hint 2. (Ans D)

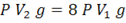

Solidification time ,

,

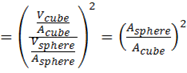

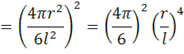

Required ratio

Question 3. Which of the following engineering materials is the most suitable material for the chamber die casting?

(A) Low carbon steel

(B) Titanium

(C) Copper

(D) Tin

GATE-ME-2007

Hint 3. (Ans B)

For hot chamber die casting, titanium is used.

Question 4. While cooling, a cubical casting of side 40 mm undergoes 3%, 4% and 5% volume shrinkage during the liquid state, phase transition and solid state, respectively. The volume of the metal compensated from the riser is

(A) 2 %

(B) 7 %

(C) 8 %

(D) 9%

GATE-ME-2008

Hint 4. (Ans B)

The riser can compensate for volume shrinkage only in the liquid stage and transition stage and not in the solid state.

Hence volume of metal that needs to be compensated from the riser =3+4=7%

Question 5. Match the items in Column I and Column II.

| Column I | Column II |

| P. Metallic Chills | 1. Support for the core |

| Q. Metallic Chaplets | 2. Reservoir for the core |

| R. Riser | 3. Control cooling of critical sections |

| S. Exothermic Padding | 4. Progressive solidification |

(A) P—1 Q—3 R—2 S—4

(B) P—1 Q—4 R—2 S—3

(C) P—3 Q—4 R—2 S—1

(D) P—4 Q—1 R—2 S—3

GATE-ME-2009

Hint 5. (Ans D)

Question 6. Two streams of liquid metal which are not hot enough to fuse properly result into a casting defect known as

(A) Cold shut

(B) Swell

(C)Sand wash

(D) Scab

GATE-ME-2009

Hint 6. (Ans A)

Question 7. In gating system, the ratio 1:2:4 reprsents

(A) Sprue base area : runner area : ingate area

(B) Pouring basin area : ingate area : runner area

(C) Pouring basin area : ingate area : Casting area

(D) Runner area : ingate area : Casting area

GATE-ME-2010

Hint 7. (Ans A)

Question 8. A cubic casting of 50 mm side undergoes volumetric solidification shrinkage and volumetric solid contraction of 4% and 6% respectively. No riser is used. Assumed uniform cooling in all directions. The side of the cube after solidification and contraction is

(A) 48.32 mm

(B) 49.90 mm

(C) 49.94 mm

(D) 49.96 mm

GATE-ME-2011

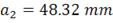

Hint 8. (Ans A)

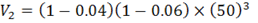

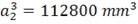

Volume of cube after solidification and contraction

Question 9. Green sand mould indicates that

(A) Polymeric mould has been cured

(B) Mould has been totally dried

(C) Mould is green in colour

(D) Mould contains moisture

GATE-ME-2011

Hint 9. (Ans D)

Green sand mould indicates that mould is not baked or dried. i.e., it contains moisture.

Question 10. A cube shaped casting solidifies in 5 min. The solidification time in min for a cube of the same material, which is 8 times heavier than the original casting, will be

(A) 10

(B) 20

(C) 24

(D) 40

GATE-ME-2013

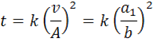

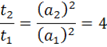

Hint 10. (Ans B)

Weight is 8 times heavier

Cube of side ‘a’

Answer Keys

1. (C) 2. (D) 3. (B) 4. (B) 5. (D) 6. (A) 7. (A) 8. (A) 9. (D) 10. (B)

5 Responses to “Previous Years Gate Questions on Casting 2007-2013”

M. BHASKAR

Question no.3- for hot chamber die casting titanum in not used. only low melting alloy like tin, zinc is used. titanium answer is wrong.

PH:9901562779

M. BHASKAR

Question no.3- for hot chamber die casting titanIum in not used. only low melting alloy like tin, zinc is used. titanium answer is wrong.

PH:9901562779

M. BHASKAR

Question no.3:- hot chamber die casting process is used only for low melting alloy like zinc and tin. titanium answer is wrong.

PH:9901562779

R.Mili

Then when we use steel and cast iron ? These two are used for parmenent mould casting ,ryt?

S SIMHACHALAM

GOOD